Revolutionizing Bulk Material Handling: Innovations and Insights

The landscape of bulk material handling is evolving rapidly, driven by advancements in technology, a growing emphasis on efficiency, and the necessity for sustainable practices. As industries globally seek to optimize their operations, the role of innovative solutions such as electronics and 3D printing becomes increasingly significant. This article delves deep into how these technologies are reshaping the bulk material handling sector, outlining benefits, best practices, and future trends.

Understanding Bulk Material Handling

Bulk material handling refers to the systems and processes involved in storing, transporting, and managing bulk materials such as grains, chemicals, metals, and minerals. The efficiency and safety of these processes are paramount, especially in sectors like construction, agriculture, and manufacturing. Key components of bulk material handling include:

- Conveyors: Essential for the transportation of bulk materials from one point to another.

- Storage Systems: Facilities designed to store materials effectively, such as silos and bins.

- Transfer Equipment: Machinery that assists in the loading and unloading of materials.

- Dust Control Systems: Strategies and systems to manage airborne particles and improve air quality.

The Role of Electronics in Bulk Material Handling

With the advent of modern electronics, bulk material handling has transformed significantly. Here are several ways in which electronics contribute to this field:

1. Automation and Control

The integration of automation in bulk material handling minimizes human intervention, thus enhancing efficiency and reducing operational errors. Automated systems equipped with sensors can:

- Monitor material levels in real-time, ensuring optimal inventory management.

- Control equipment based on predetermined parameters, reducing the risk of accidents.

- Streamline operations through data analytics, improving decision-making processes.

2. Enhanced Safety Measures

As industries operate under increasingly stringent safety regulations, electronic safety systems have become vital. These may include:

- Emergency Stop Systems: Allow for immediate cessation of operations in case of emergencies.

- Wearable Technology: Devices that monitor the vital signs of workers and alert supervisors in case of distress.

- Automated Alerts: Notifying personnel of equipment malfunctions or safety breaches in real-time.

3. Predictive Maintenance

Through the use of advanced sensors and IoT (Internet of Things), businesses can implement predictive maintenance strategies. This allows for:

- Preemptive repairs before a potential failure occurs, ultimately saving costs and reducing downtime.

- Data Collection: Analyzing data patterns to anticipate required maintenance schedules.

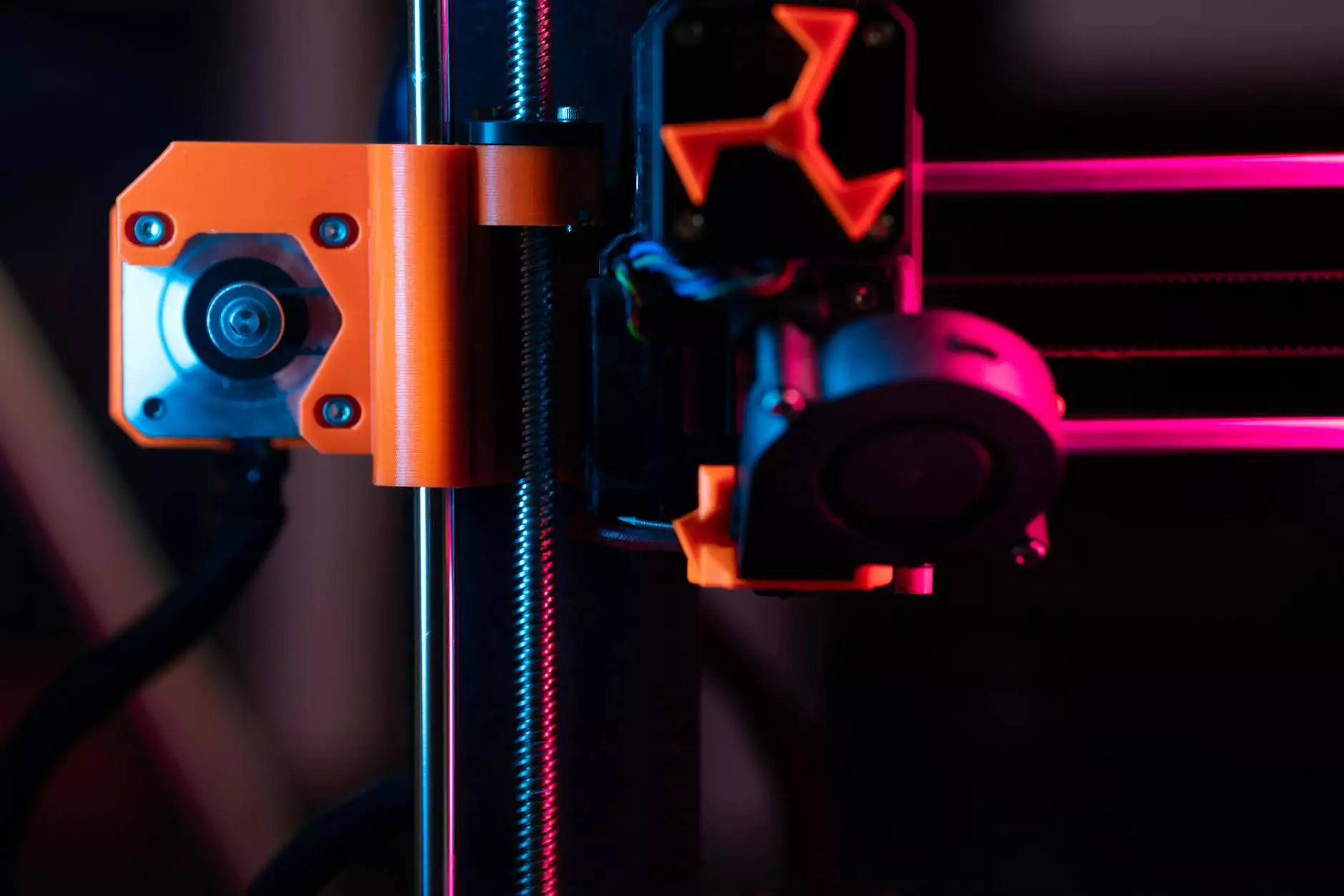

The Impact of 3D Printing in Bulk Material Handling

3D printing has rapidly emerged as a disruptive technology in various industries, including bulk material handling. Its influence can be observed in several key areas:

1. Custom Tooling and Machinery Parts

The ability to create custom components on demand is a game-changer. Companies can now:

- Produce specialized tools: Hence reducing lead time for equipment modifications.

- Fabricate spare parts: On-site, minimizing downtime and logistical issues associated with part replacements.

2. Prototyping and Design Innovation

With 3D printing, businesses can quickly develop and test new designs, leading to:

- Enhanced design flexibility: Allowing for experimentation with materials and structures.

- Reduced Costs: Cutting down expenses associated with traditional prototyping methods.

3. Efficient Production Processes

3D printing enables manufacturers to streamline their production processes by:

- Reducing material waste: Utilizing only the necessary material for each component.

- Facilitating rapid production cycles: Enhancing overall efficiency in systems that rely heavily on bulk material handling.

Best Practices for Effective Bulk Material Handling

Implementing best practices is essential for optimizing bulk material handling operations. Here are several strategies to consider:

1. Evaluate and Upgrade Equipment

Regular assessments of handling equipment are vital. Older machinery may not meet contemporary safety or efficiency standards. Investing in modern technology can lead to:

- Increased throughput capabilities.

- Enhanced safety features that comply with regulations.

- Improved maintenance routines extending equipment lifespans.

2. Training and Continued Education

Ensuring that employees are well-trained in using both traditional and new technologies is crucial. Regular training sessions should cover:

- Safe operational procedures.

- How to leverage new technologies effectively.

- Emergency response tactics to mitigate risks.

3. Implementing Sustainable Practices

With a growing focus on sustainability, adopting eco-friendly practices can significantly benefit bulk material handling operations. Consider:

- Minimizing energy consumption through efficient machinery.

- Utilizing recycling methods for materials where applicable.

- Investing in systems that reduce dust and pollutants.

Future Trends in Bulk Material Handling

The future of bulk material handling will likely be shaped by the following trends:

1. Increased Automation

As technology continues to advance, the reliance on automation will become even more pronounced. This will increase productivity while minimizing the labor force required for manual handling tasks.

2. Integration of AI and Machine Learning

The use of AI and machine learning will transform how data is processed and operational decisions are made. Expect systems that can learn from past operations to optimize future performance.

3. Sustainability Integration

With growing environmental concerns, the movement towards sustainable bulk material handling solutions will gain momentum, leading to increased efficiency and reduced environmental impacts.

Conclusion

In summary, the bulk material handling sector is poised for significant transformation driven by innovations in electronics and 3D printing. As we embrace these technologies, businesses can expect improved efficiency, enhanced safety, and more sustainable operations. For organizations looking to gain a competitive edge, investing in these innovative practices is not merely an option; it is a necessity for future success.

For more insights and solutions tailored to your business needs in bulk material handling, consider visiting Polygon Machinery. Let’s build a more efficient future together!