Understanding the Revolution in Printing: The Breakthrough of UV Machine Printing

UV machine printing has emerged as a groundbreaking technology in the printing industry, changing how businesses approach production. This innovative method leverages ultraviolet (UV) light to cure inks as they are printed, significantly enhancing quality, speed, and versatility. As the demands for high-quality prints and swift turnaround times continue to rise, understanding the profound impact of UV printing technology is essential for businesses aiming to stay ahead.

The Basics of UV Machine Printing

Before delving deeper, it is crucial to understand what UV machine printing entails. Unlike traditional printing methods that rely on solvent-based inks that take time to dry, UV printing uses special inks that become solid when exposed to UV light. This immediate curing process not only preserves the colors and vibrancy but also allows for printing on a wide range of materials including:

- Paper

- Plastic

- Metal

- Glass

- Wood

- Acrylic

- Textiles

This versatility opens up a myriad of opportunities for businesses looking to diversify their product offerings and reach new markets.

The Advantages of UV Machine Printing

1. Exceptional Print Quality

One of the primary reasons businesses are turning to UV machine printing is the remarkable print quality it delivers. The UV curing process ensures that the ink adheres robustly to the substrate, resulting in sharper images, more vibrant colors, and enhanced detail. This is particularly important in competitive industries where visual appeal can make or break a sale.

2. Fast Drying Times

In today’s fast-paced market, speed is of the essence. Traditional inks often require extensive drying times, which can lead to bottlenecks in production. In contrast, UV cured inks dry instantly under UV lamps. This rapid curing process minimizes downtime and allows for quicker job turnaround, thus improving overall efficiency in production.

3. Environmentally Friendly

UV machine printing is paving the way for more sustainable printing practices. The inks used contain fewer volatile organic compounds (VOCs), making them less harmful to the environment. Furthermore, because the inks are cured rather than absorbed, there is less waste during the printing process. This eco-friendly aspect can strengthen a brand's image in increasingly environmentally-conscious markets.

4. Flexibility with Material Choices

As mentioned earlier, UV printing can be conducted on a multitude of surfaces. This flexibility means businesses can offer unique products tailored to various industries without being constrained by the limitations of traditional printing methods. Whether it’s creating promotional materials, custom signage, or unique gifts, the ability to print on diverse substrates greatly expands creative possibilities.

5. Durability and Resistance

The durability of UV prints is another significant advantage. Once cured, the ink adheres to the material more effectively than traditional inks and displays exceptional resistance to scratches, fading, and even harsh weather conditions. For businesses involved in outdoor advertising or product packaging, this durability translates into long-lasting, high-quality prints.

Applications of UV Machine Printing

The applications for UV machine printing are vast and varied. Below are some notable areas where this technology has made a significant impact:

1. Packaging

In the packaging industry, UV printing enhances the appearance and durability of packaging materials. Brands can achieve stunning graphics that not only attract customers but also withstand the rigors of handling and shipping. Moreover, short-run packaging jobs can be completed quickly, accommodating the needs of both large and small production runs.

2. Signage and Display Graphics

UV printing is extensively used for signage and graphics that require both indoor and outdoor applications. From vibrant banners to intricate signs, the ability to print on rigid substrates allows for eye-catching displays that stand the test of time.

3. Promotional Products

Businesses can leverage UV machine printing to create customized promotional products ranging from pens and mugs to tote bags and keychains. This method ensures that every item has a professional finish that can significantly enhance brand visibility.

4. Fine Art and Photography

Artists and photographers are increasingly adopting UV printing technology to reproduce their work. The accuracy and vibrancy of colors make UV printing an excellent choice for producing fine art prints that replicate the original pieces faithfully.

5. Industrial Applications

In industrial environments, UV printing is used for labeling and coding products that require high durability and resistance to chemicals. This reliability is critical for compliance and traceability in various industries, including pharmaceuticals and food and beverage.

Choosing the Right UV Machine Printing Provider

When seeking a provider for UV machine printing, several factors must be considered. Ensuring that your printing partner can meet high-quality standards while also delivering timely results is vital for your business reputation.

1. Quality Standards

Always inquire about the quality control measures that a printing service has in place. Your chosen provider should be able to showcase their previous work to demonstrate their capabilities in producing high-quality prints.

2. Experience and Expertise

Look for a company with a proven track record in UV printing. Experience in handling various materials and complex projects will indicate that they can meet your specific requirements.

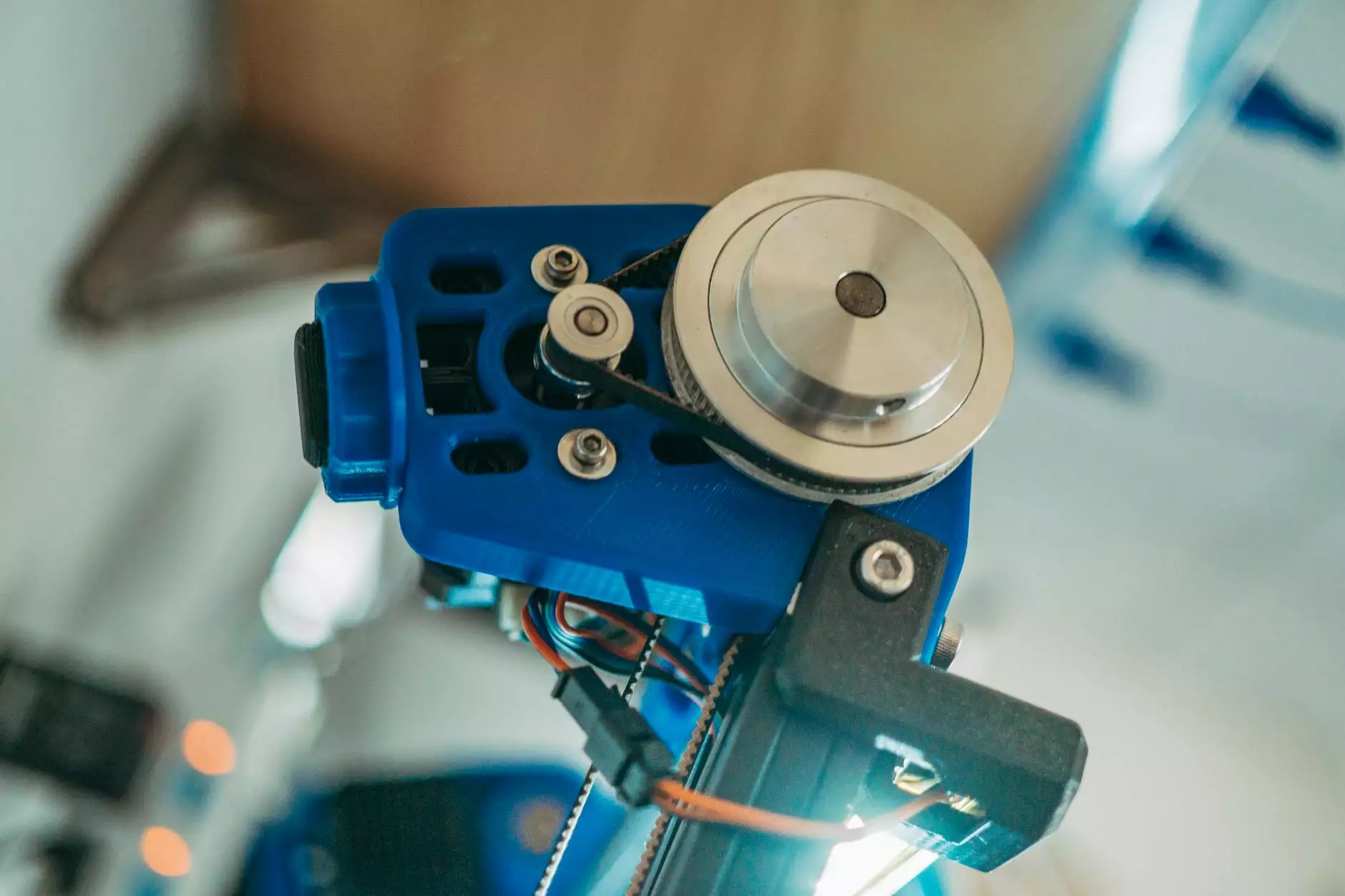

3. Equipment and Technology

The technology used in UV printing can vary significantly. Ensure that the provider uses state-of-the-art equipment that adheres to the latest industry standards. This investment in technology translates to superior print quality and efficiency.

4. Customer Service

Efficient customer service is a hallmark of a great printing partner. You should expect prompt responses to inquiries, professional consultations, and clear communication throughout the project timeline.

5. Pricing Structure

While cost should never be the sole determining factor, it is essential to understand the pricing structure of your printing services. Compare costs among providers, but keep in mind that the cheapest option may not always guarantee the best quality.

Conclusion: Embracing the Future of Printing

The transition towards UV machine printing is not just a trend; it is a paradigm shift that is setting new standards for quality, efficiency, and sustainability in the printing industry. As technology continues to evolve, businesses that embrace UV printing will find themselves at the forefront of innovation, providing exceptional products that meet the ever-growing demands of consumers.

At Boston Industrial Solutions, we are committed to delivering top-tier printing services that harness the power of UV machine printing. Whether you are looking for high-quality packaging, stunning signage, or brilliant promotional products, our expertise ensures that your projects not only meet but exceed expectations.

Explore our diverse range of services and discover how UV machine printing can elevate your business today.