Design Your First PCB with Autodesk Fusion 360

Blog

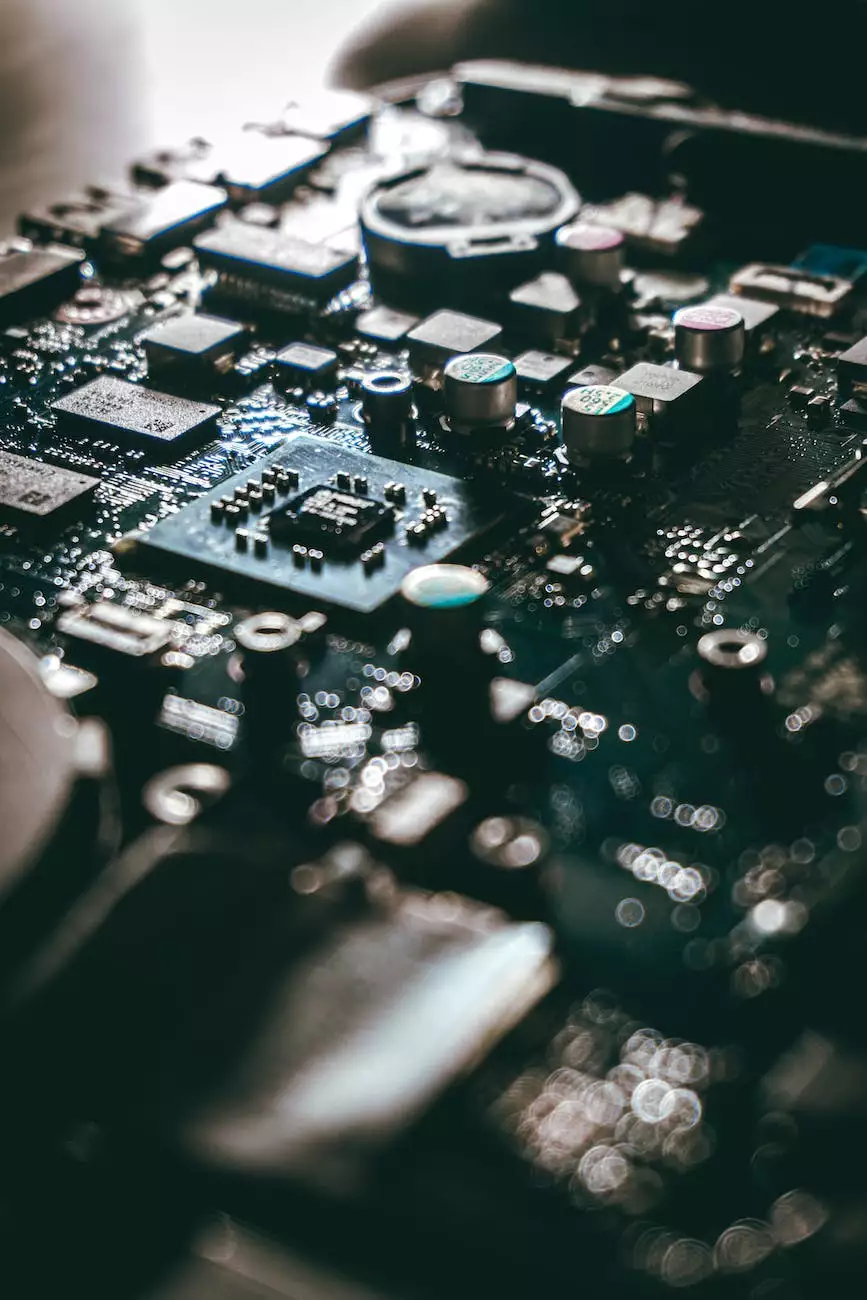

Welcome to OrangeCoastWeb, your premier destination for professional website development services in the business and consumer services industry. In this comprehensive guide, we will walk you through the process of designing your first Printed Circuit Board (PCB) using Autodesk Fusion 360, a powerful software solution for mechanical and electrical design.

Understanding PCB Design

Before we dive into the intricacies of designing your first PCB, let's take a moment to understand what a PCB is and its importance in modern electronic devices.

A Printed Circuit Board, or PCB, is a vital component of electronic devices, acting as a platform for connecting and supporting various electrical components. It provides a compact and reliable solution for interconnecting electronic components, reducing the size and complexity of circuits.

Designing a PCB requires careful planning and consideration of various factors, including component placement, signal integrity, power distribution, and thermal management. With Autodesk Fusion 360, you have a comprehensive toolset that simplifies the entire design process.

The Benefits of Autodesk Fusion 360

Autodesk Fusion 360 is a cutting-edge software solution that combines mechanical and electrical design capabilities, making it a perfect choice for PCB design. Here are some key benefits of using Fusion 360:

Seamless Integration

With Fusion 360, you can seamlessly transition between mechanical and electrical design, ensuring a holistic approach to PCB development. This integration enables you to optimize your design, improve collaboration between teams, and reduce time-to-market.

Powerful Design Tools

Fusion 360 offers a wide range of powerful design tools tailored specifically for PCB design. From component libraries to schematic capture and PCB layout tools, Fusion 360 provides everything you need to build complex and reliable PCBs.

Real-Time Collaboration

Collaboration is essential in any design process. Fusion 360 eliminates barriers to collaboration by providing real-time collaboration features. Whether you are working with a remote team or collaborating with a client, Fusion 360 enables seamless communication and sharing of design data.

Simulation and Analysis

Testing the performance of your PCB design is crucial to its success. Fusion 360 offers simulation and analysis capabilities, allowing you to validate your design before prototype production. This helps identify potential issues and optimize the design for efficiency and functionality.

Step-by-Step Guide to Designing Your First PCB

Now that we have acquainted ourselves with the benefits of Autodesk Fusion 360, let's delve into the step-by-step process of designing your first PCB. This guide will provide you with comprehensive instructions to ensure a successful PCB design.

Step 1: Define Your Design Requirements

Before you start designing your PCB, it's crucial to define your design requirements. Consider factors such as the size, functionality, and power requirements of your circuit. Clearly defining your design parameters will streamline the entire design process.

Step 2: Create the Schematic

The next step is to create the schematic for your PCB design. Use Fusion 360's schematic capture tool to add components, connect them, and define their electrical characteristics. Ensure proper labeling and documentation for clarity.

Step 3: Design the PCB Layout

Once the schematic is complete, it's time to design the PCB layout. Fusion 360's PCB layout tools offer a user-friendly interface, allowing you to place components, route traces, and define copper pour areas. Pay close attention to signal integrity and thermal management while designing the layout.

Step 4: Verify and Optimize

After completing the PCB layout, it's essential to verify and optimize your design. Use Fusion 360's simulation and analysis features to perform checks for design rule violations, signal integrity issues, and thermal considerations. Make necessary adjustments and optimizations to ensure a robust design.

Step 5: Generate Manufacturing Files

Once your PCB design is finalized, it's time to generate the manufacturing files. Fusion 360 simplifies this process by providing built-in tools to generate Gerber files, bill of materials (BOM), and other manufacturing documentation. Ensure all necessary files are created and double-check for accuracy.

Step 6: Prototype and Testing

With your manufacturing files ready, it's time to move on to the prototyping stage. Prototype your PCB design using a reputable PCB manufacturer, and thoroughly test the functionality and performance of the circuit. Make any necessary iterations to improve the design if required.

Step 7: Production and Deployment

Once the prototype has been tested and approved, you can proceed with the production and deployment of your PCB design. Choose a reliable manufacturer to produce your PCBs in large quantities, ensuring quality control throughout the production process.

Contact OrangeCoastWeb for Professional PCB Design Services

At OrangeCoastWeb, we understand the importance of high-quality PCB design in today's technological landscape. With our expertise in website development and design, we offer top-notch PCB design services using Autodesk Fusion 360. Partner with us to ensure a successful and efficient PCB development process.

Our team of skilled professionals is well-versed in Fusion 360's capabilities and can assist you in designing and optimizing your PCB for optimal performance and reliability. Contact OrangeCoastWeb today to discuss your PCB design requirements and take your electronic device to the next level.